Ensuring Reliability, Accuracy, and Compliance—Nationwide

In today’s regulatory landscape, environmental monitoring is not just a compliance requirement—it’s a strategic imperative. At NK Square Solutions, we specialize in comprehensive Annual Maintenance Contracts (AMC) for a wide range of pollution monitoring equipment, ensuring your systems operate at peak performance year-round.

With a team of nearly 20 skilled engineers deployed across multiple sites in India, we deliver end-to-end support that is both responsive and reliable. Whether you're monitoring air quality, water discharge, noise levels, or industrial emissions, our AMC services are designed to minimize downtime, optimize accuracy, and extend the life of your equipment.

Why Choose Us?

🔧 OEM-Agnostic Expertise We understand that your infrastructure may include equipment from multiple manufacturers. Our engineers are trained to service and calibrate instruments from all major OEMs, ensuring seamless support regardless of brand or model. This flexibility allows us to tailor our services to your specific setup without bias or limitation.

🌐 Pan-India Coverage Our footprint spans industrial hubs, remote installations, and urban centers alike. With engineers stationed across India, we guarantee timely service visits, rapid response to breakdowns, and consistent performance monitoring—no matter where your operations are located.

🔄 End-to-End Service Delivery From preventive maintenance and calibration to emergency repairs and compliance reporting, our AMC offering covers the full lifecycle of your pollution monitoring systems. We take ownership of every aspect, so you can focus on your core operations with confidence.

📊 Data-Driven Maintenance Our approach is rooted in analytics. We track performance metrics, service history, and calibration drift to proactively schedule interventions. This minimizes reactive maintenance and ensures your equipment remains audit-ready at all times.

Scope of Services

Our AMC packages are designed to be comprehensive, customizable, and compliant with CPCB and SPCB guidelines. Key service components include:

Routine Preventive Maintenance Scheduled visits for cleaning, inspection, and functional testing of sensors, analyzers, and control units.

Calibration and Certification Periodic calibration using certified standards, with documentation suitable for regulatory audits.

Breakdown Support Rapid response to equipment failures, including onsite diagnostics and repairs.

Spare Parts Management Inventory planning and replacement of critical components to avoid unexpected downtime.

Software and Firmware Updates, ensuring your systems run the latest versions for optimal performance and security.

Compliance Reporting Assistance Support in generating and validating data reports for submission to pollution control boards.

Remote Monitoring and Alerts Integration with cloud platforms for real-time data access, alerts, and predictive maintenance.

Equipment We Support

Our AMC services cover a wide spectrum of pollution monitoring instruments, including but not limited to:

Continuous Ambient Air Quality Monitoring Stations (CAAQMS)

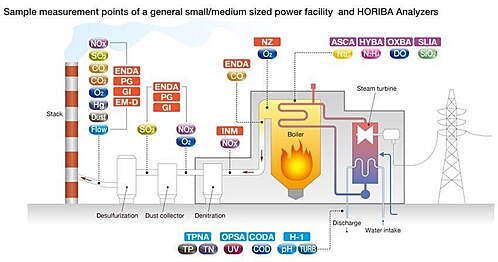

Continuous Emission Monitoring Systems (CEMS)

Effluent Quality Monitoring Systems (EQMS)

Noise Monitoring Terminals

Meteorological Sensors

Portable Gas Analyzers

Dust and Particulate Monitors

Water Quality Sensors (pH, DO, TSS, etc.)

Whether your systems are standalone or integrated into SCADA or cloud platforms, we ensure seamless upkeep and interoperability.

Our Team: Skilled, Certified, Committed

Our engineering team is the backbone of our AMC services. With nearly 20 professionals stationed across India, we bring:

Multi-disciplinary Expertise Electrical, mechanical, instrumentation, and software specialists working in tandem.

Certifications and Training Regular upskilling in OEM protocols, safety standards, and regulatory compliance.

Site Familiarity Engineers familiar with your plant layout, operational constraints, and reporting needs.

Customer-Centric Approach Transparent communication, proactive scheduling, and a commitment to minimizing disruption.

Value We Deliver

💡 Operational Continuity Avoid costly downtime and ensure uninterrupted data collection for compliance and decision-making.

📉 Cost Efficiency Preventive maintenance reduces long-term repair costs and extends equipment lifespan.

📈 Regulatory Confidence Stay audit-ready with calibrated, certified instruments and well-documented service records.

🔒 Data Integrity Ensure accurate, tamper-proof readings that stand up to scrutiny from regulators and stakeholders.

🤝 Trusted Partnership We don’t just service equipment—we build long-term relationships based on trust, transparency, and performance.

Flexible AMC Plans

We offer tiered AMC packages to suit different operational needs and budgets:

| Plan Type | Features | Ideal For |

|---|---|---|

| Basic | Preventive maintenance, calibration, documentation | Small facilities, low-frequency use |

| Standard | Includes breakdown support, spare parts planning | Mid-sized operations |

| Premium | Full lifecycle support, remote monitoring, compliance assistance | Large-scale, multi-site setups |

Custom plans are available for clients with unique requirements or legacy systems.

Let’s Build a Cleaner, Smarter Future

Environmental responsibility begins with reliable data. Our AMC services ensure that your pollution monitoring infrastructure remains accurate, compliant, and future-ready. Whether you're a manufacturing plant, a utility provider, or a government agency, we’re here to support your mission with professionalism and precision.

📞 Contact Us Today Let’s discuss how our AMC solutions can be tailored to your site, equipment, and compliance goals.

EnviroMonitor is a multi-device multiprotocol compatible data acquisition and management software. The software has an installed base of over 650 units across India and complies with the data management guidelines of various state Pollution Control Bodies as well as CPCB, New Delhi.

ENVIRO MONITOR consists of a suite of user-friendly reports that serve the needs of internal teams as well as compliance requirements. Reports that are part of the current version are

- Live dashboard

- Data / statistical reports

- Diurnal reports

- Alarm reports

- Summary Reports – Daily, Monthly, Yearly

- Automated reports through email

- Automated alerts through email and SMS

Continuous Emission Monitoring Systems (CEMS)

Continuous Emission Monitoring Systems (CEMS) are advanced, automated solutions that track and report real-time emissions from industrial stacks. These systems measure key pollutants such as Particulate Matter (PM), Sulphur Dioxide (SO₂), Nitrogen Oxides (NOₓ), Carbon Monoxide (CO), Ammonia (NH₃), and Volatile Organic Compounds (VOCs), ensuring industries operate within prescribed environmental norms.

In India, the Central Pollution Control Board (CPCB)—under the Ministry of Environment, Forest and Climate Change (MoEF&CC)—has made CEMS mandatory for high-polluting industries. This directive stems from key environmental legislations:

Water (Prevention and Control of Pollution) Act, 1974

Air (Prevention and Control of Pollution) Act, 1981

Environment (Protection) Act, 1986

Since 2014, CPCB has issued multiple mandates requiring industries such as power plants, cement, pharmaceuticals, and tanneries to install online emission monitoring systems. The 2018 notification (G.S.R. 96(E)) expanded this requirement to include boilers in sectors like sugar, textiles, and chemicals. The latest 2024 guidelines further standardize measurement techniques and broaden the scope of monitored parameters.

Industries must transmit real-time emissions data to CPCB and State Pollution Control Boards (SPCBs) via secure Data Acquisition Systems (DAS). This ensures regulatory oversight, public transparency, and swift enforcement in case of violations.

Real-time monitoring is no longer a compliance luxury—it’s a strategic necessity. CEMS empowers industries to:

✅ Detect exceedances instantly and take corrective action

✅ Build trust with regulators and clients through transparent operations

✅ Avoid penalties, shutdowns, and legal complications

✅ Streamline reporting and reduce manual errors

By aligning with CPCB’s vision for cleaner, data-driven industrial practices, CEMS positions your business as a responsible, future-ready player in environmental compliance.

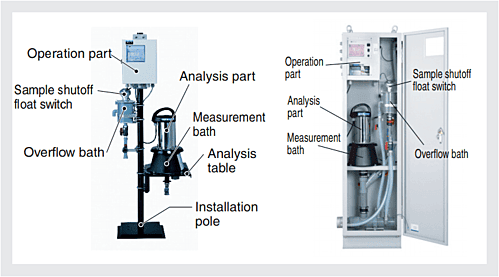

Effluent Quality Monitoring System

Effluent Quality Monitoring Systems (EQMS), also referred to as Continuous Effluent Quality Monitoring Systems (CEQMS), are automated, real-time systems designed to monitor the quality of industrial effluents before discharge. These systems are critical for ensuring that wastewater released into the environment meets regulatory standards and does not harm public health or ecosystems.

In India, the Central Pollution Control Board (CPCB) has mandated the installation of EQMS in grossly polluting industries (GPIs) and common pollution control facilities such as:

Common Effluent Treatment Plants (CETPs)

Sewage Treatment Plants (STPs)

Tanneries, distilleries, pulp & paper, sugar mills, and more

This directive was first issued in February 2014 under:

Section 18(1)(b) of the Water (Prevention and Control of Pollution) Act, 1974

Environment (Protection) Act, 1986

Industries discharging into the Ganga River and its tributaries were prioritized, with a mandate to install online monitoring systems and transmit data to CPCB and respective State Pollution Control Boards (SPCBs) via the RTDMS portal.

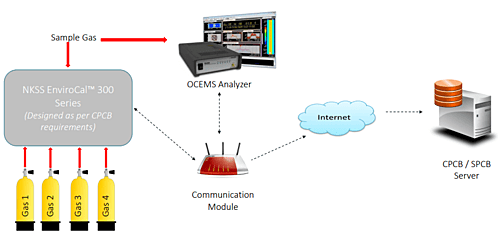

Real time remote calibration - AS per CPCB guidelines

The instruments/ analysers for real time monitoring of gaseous emissions shall be calibrated with respect to their functioning, drift, linearity detection limit, output, operating temperature and other relevant parameters and the system shall be rechecked for its health and data accuracy and reliability, following multipoint calibration (at least 03 span concentrations) using standard methods and certified reference materials. NKSS has implemented a system that checks for the zero calibration and span calibration check for the analyzers. We have through remotely, and submitting the results to CPCB. In fact, we are the first one’s in the market to design and manufacture a customized device NKSS EnviroCal™ device that performs multipoint calibration designed our NKSS EnviroCal™ device in such a way that it suits and works for any make of the analyzer.

The data comparison and calibration verification shall be done by CPCB. The health of the instruments/analyzers shall be assessed on daily basis at fixed time by checking the zero drift. The instruments/ analysers shall be rechecked for zero and span drift using standard methods and standard reference materials. The drift needs to be recorded and suitably incorporated in the data collected over the period. NK Square has implemented the online remote calibration check facility at various industries and demonstrated the same to CPCB and SPCB’s. During the online remote calibration check is being performed, we record the diagnostics data and submitting the same to CPCB for their reference, which defines the healthiness of the instrument. CPCB is verifying the calibration check results after performing it.